AUTOMOTIVE

AUTOMOTIVE

Laser marker for automotive industry

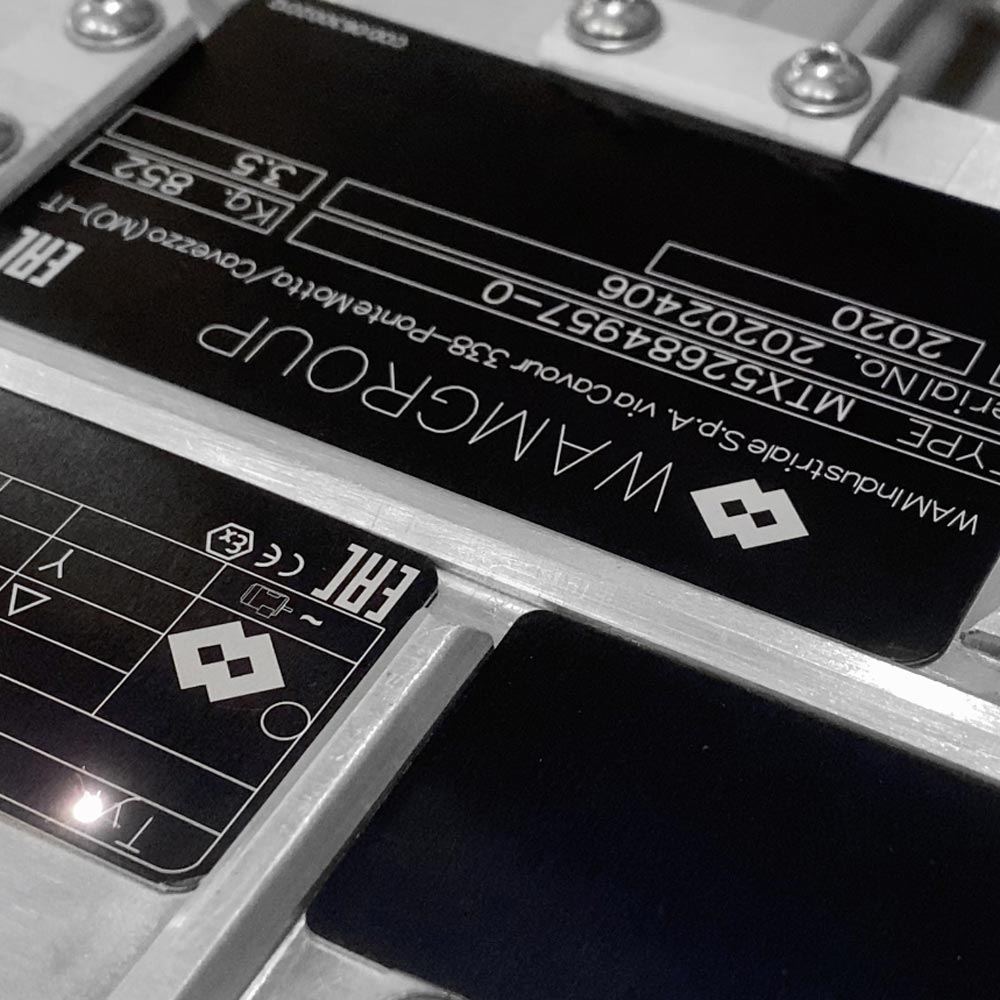

In the automotive industry, traceability plays a key role. Controlling the production chain is key to increasing productivity and reducing costs. So tracking components from different suppliers is the main demand of companies belonging to the automotive industry.

All automotive components have a recognition code: a Barcode, a QRcode or a DataMatrix. Through these codes, the manufacturer, production batch, date and factory where the component was made can be traced.

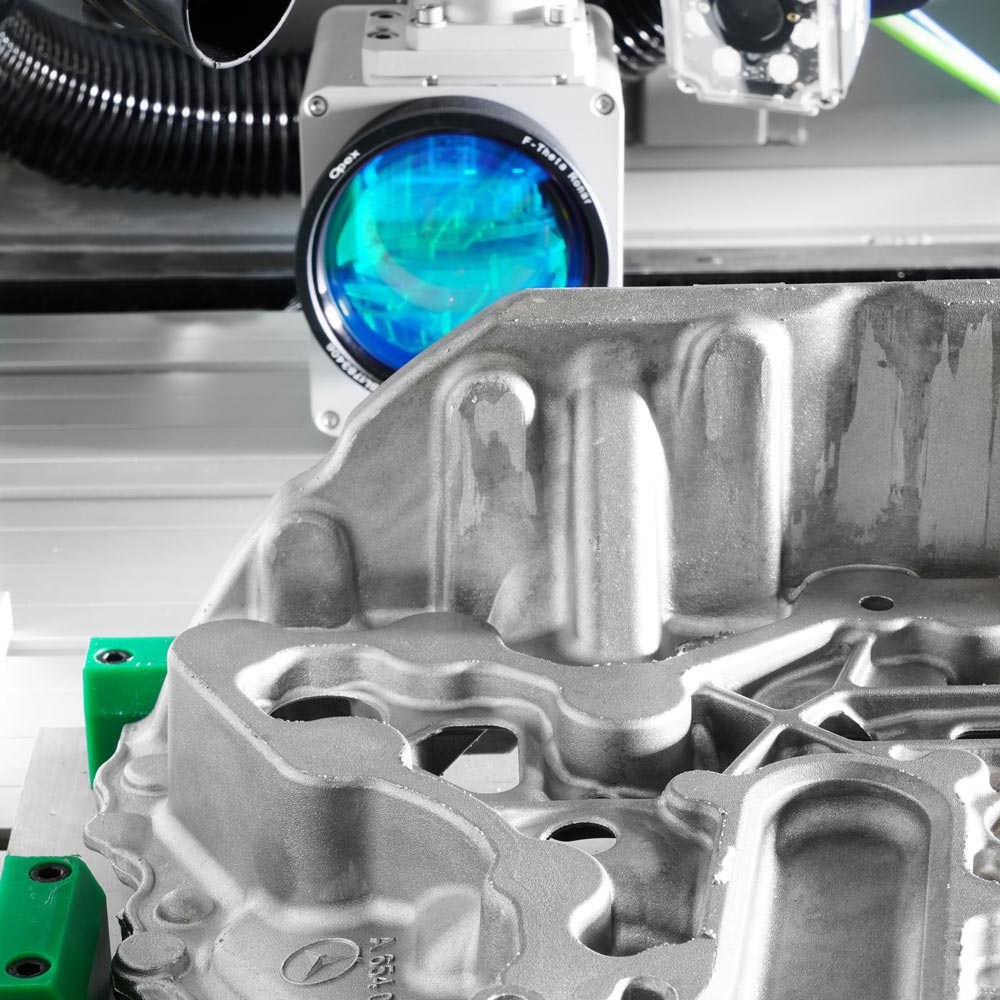

Laser marking is the traceability tool of automotive component manufacturers. All metal and plastic automotive components require laser marking. Arca can provide laser markers or laser marking stations for any component: engine plates, wiring harnesses, engine head, brake discs, gears, die castings, cutters, windshields, and tires.

Laser marking is indelible and the contrast is always high. The most commonly used laser is the fiber source laser with power ranging from 20 to 100 watts. Not overlooked, however, are fiber MOPA and DPSS laser markers for even sharper resolution. ARCA laser markers also perform reading and grading of the marked code and part traceability if a vision system is installed.