DISCOVER OUR RANGE

LASER MARKING STATIONS

CHOOSE EXACTLY WHAT YOU NEED

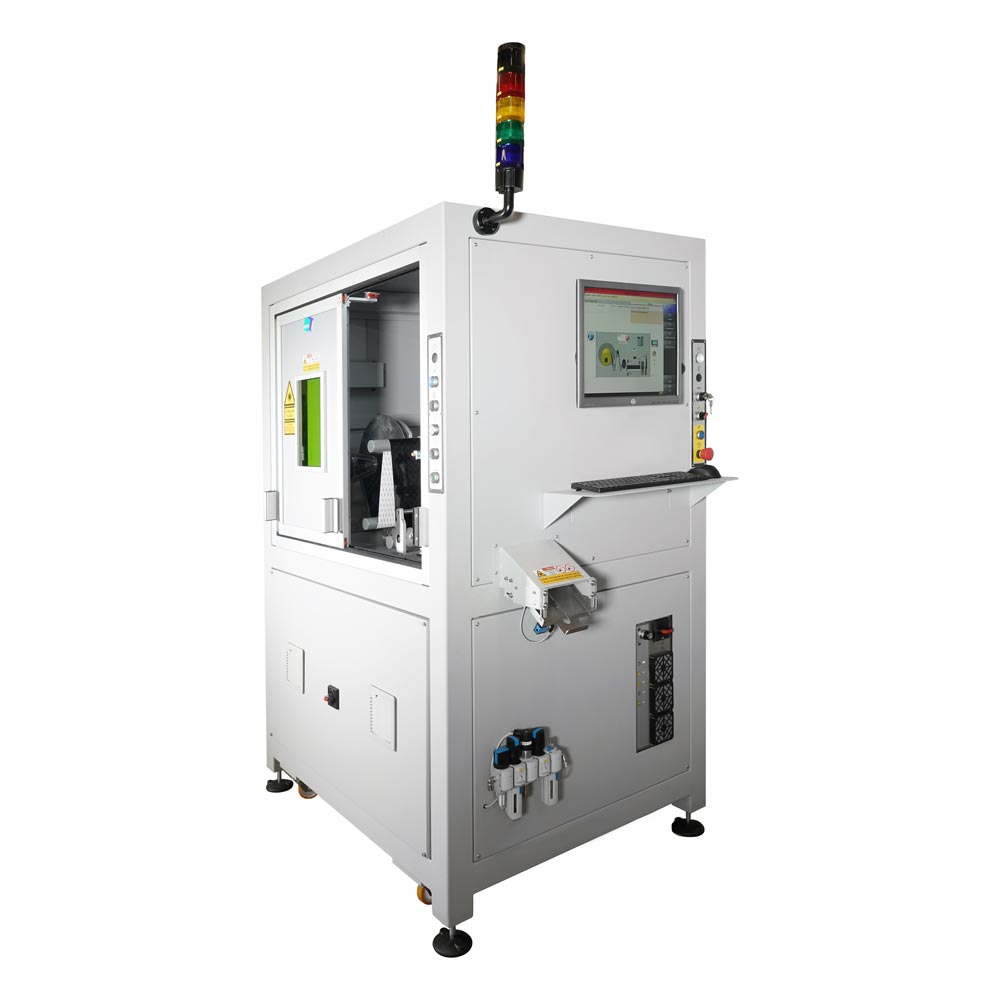

Laser marking stations are sturdy made of scratch-resistant epoxy powder-coated steel and designed for industrial environments. They are available in compact 840mm length and 1240mm version. The 1240mm marking station is in a condition to accommodate handling systems for the products to be marked (robots) and handling systems for the marker itself.

It can also be equipped with a rotary table for increased productivity even when manually loading the single piece.

The outline of the station and the positioning of the control buttons allow optimal approach for best operation. Side panels can be manually openable to facilitate maintenance and position adjustment of the marker (when manual).

Or, equipped with accesses for product transit on conveyor. The main opening and position adjustment of the laser marker can both be manual or automatic. The marking station can be equipped with a container for collecting nonconforming products.

DISCOVER OUR RANGE

LASER MARKING STATIONS

CHOOSE EXACTLY WHAT YOU NEED

Laser marking stations are sturdy made of scratch-resistant epoxy powder-coated steel and designed for industrial environments. They are available in compact 840mm length and 1240mm version. The 1240mm marking station is in a condition to accommodate handling systems for the products to be marked (robots) and handling systems for the marker itself.

It can also be equipped with a rotary table for increased productivity even when manually loading the single piece.

The outline of the station and the positioning of the control buttons allow optimal approach for best operation. Side panels can be manually openable to facilitate maintenance and position adjustment of the marker (when manual).

Or, equipped with accesses for product transit on conveyor. The main opening and position adjustment of the laser marker can both be manual or automatic. The marking station can be equipped with a container for collecting nonconforming products.

Laser marking stations

Laser marking stations

LASER MARKING STATIONS FOR AUTOMOTIVE COMPONENTS

- 1 fiber laser marker with data matrix code reader.

- automatic front opening and opening side for easy access to adjustments.

- Before marking, the surface is “bleached” by the marker to enable the verification of readability of the code, on reflective materials.

LASER MARKING STATION FOR ELECTRICAL COMPONENTS

- Semi-automatic fiber laser marking system.

- Also performs electrical function test of the product and visual inspection of assembly correct: exact components (with discrimination of shape and color) and in suitable position.

- The part to be marked is manually positioned.

- The automatic sliding closure includes safety barriers photoelectric.

- Safety container for defective products with automatic reconciliation controlled via software.

LASER MARKING STATION FOR TAPS AND HYDRAULIC COMPONENTS

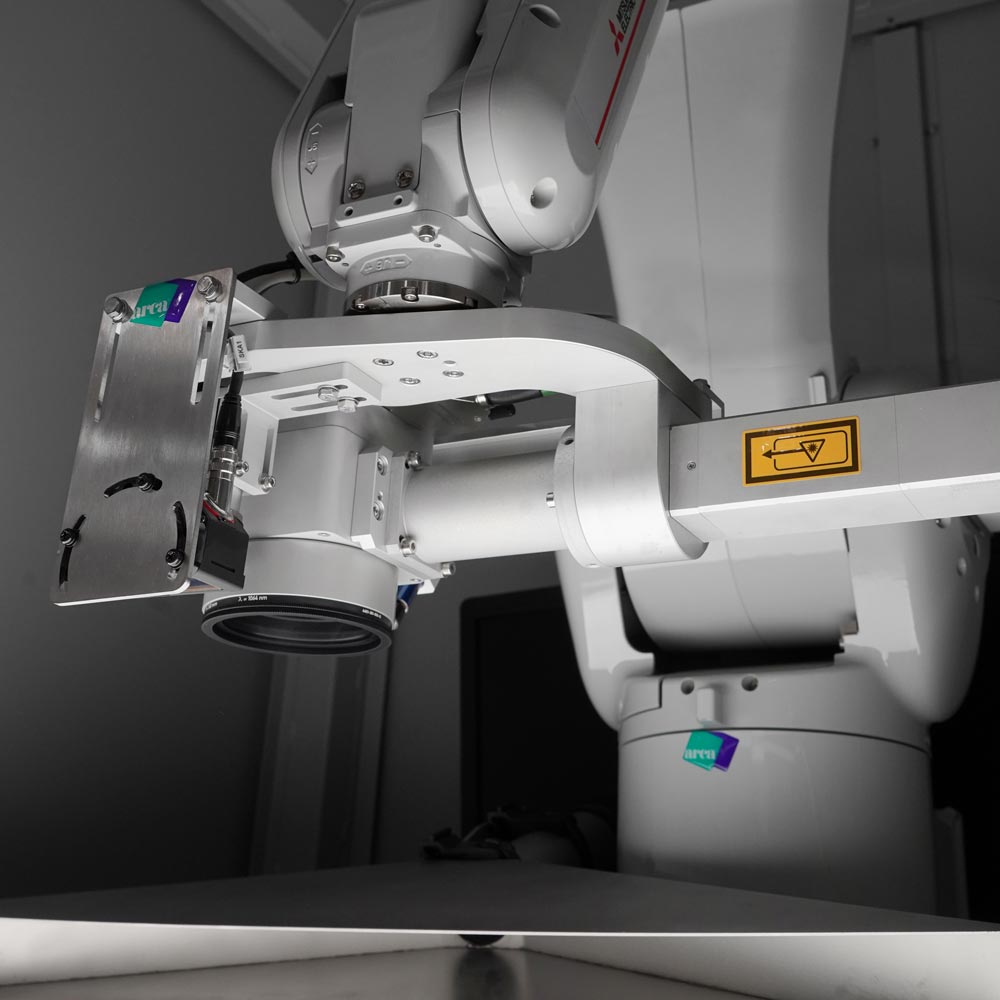

- Laser marking system for products with different shapes and finishes, without the need for positioning templates.

- It integrates a high-precision vision system that detects each piece and its shape, automatically positioning the marker at the correct focal distance.

- 4.0 integration with the customer’s information system.

- Infinite possibilities for personalizing the data also for traceability purposes.

- Possibility of simultaneous loading of several pieces to optimize production.

- Facilitated loading by displaying the shape of the products on the support surface.

LASER MARKING STATIONS FOR CONTACT LENSES

- System for micromarking contact lenses.

- System for micromarking contact lenses. It integrates a high-resolution vision system in a condition to detect the lens profile and a positioning device automatic (overall accuracy of 0.01 mm) 4.0 integration with the customer’s information system. Endless possibilities of data customization even for the traceability purposes.

- Facilitated loading system with approach of the part to the operator.

LASER MARKING STATION FOR SELF-ADHESIVE LABELS

- System for the production of self-adhesive labels, packaged in sheets, by die-cutting and laser marking.

- Typically used in the automotive and where convenient to apply manual.

- It employs standard or, durable materials that are sensitive to the laser.

- 4.0 integration with the customer’s information system.

- Controlled print-pickup sequence.

- Endless possibilities for customization of the data and outline of each label.

- Patented pull and cut system to neutralize the effects of adhesive (dirt and jams).

Download our catalogue

Discover the laser marker that’s right for you and all our products with our thematic monographs

Download our catalogue

Discover the laser marker that’s right for you and all our products with our thematic monographs